Say-Mak

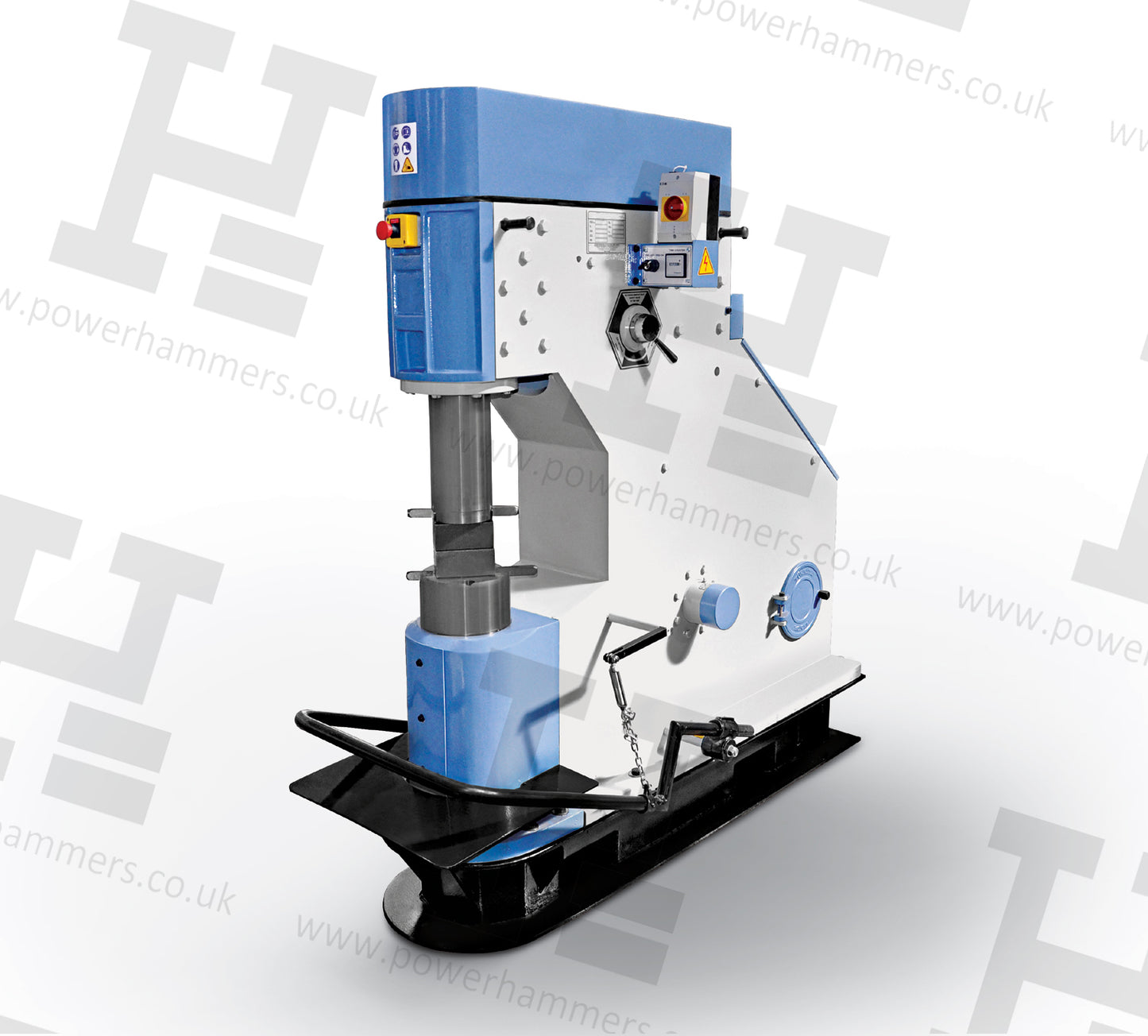

Say-Mak SPH-60

Say-Mak SPH-60

Request a Quote

Fill out the form for a personalised quote and guidance on the right machine for your work.

The Say-Mak SPH-60 is a versatile and powerful pneumatic forging hammer designed for precision and durability. Built for demanding blacksmithing tasks, the SPH-60 excels in flat die and drop forging applications, offering reliable performance to workshops of all sizes.

Key Features

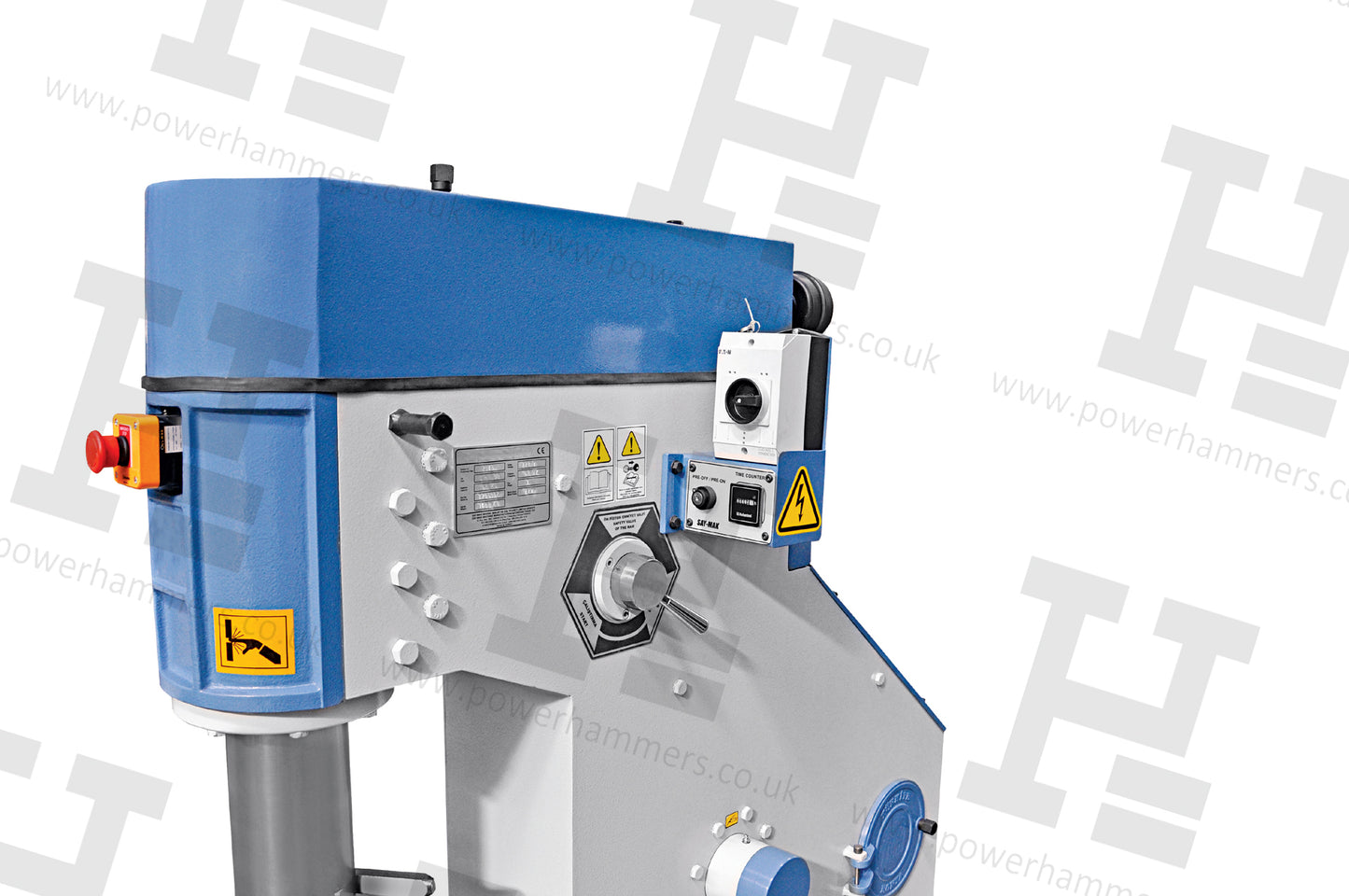

- Exceptional Power: A 60 kg ram weight delivers consistent, high-impact force for tough forging operations.

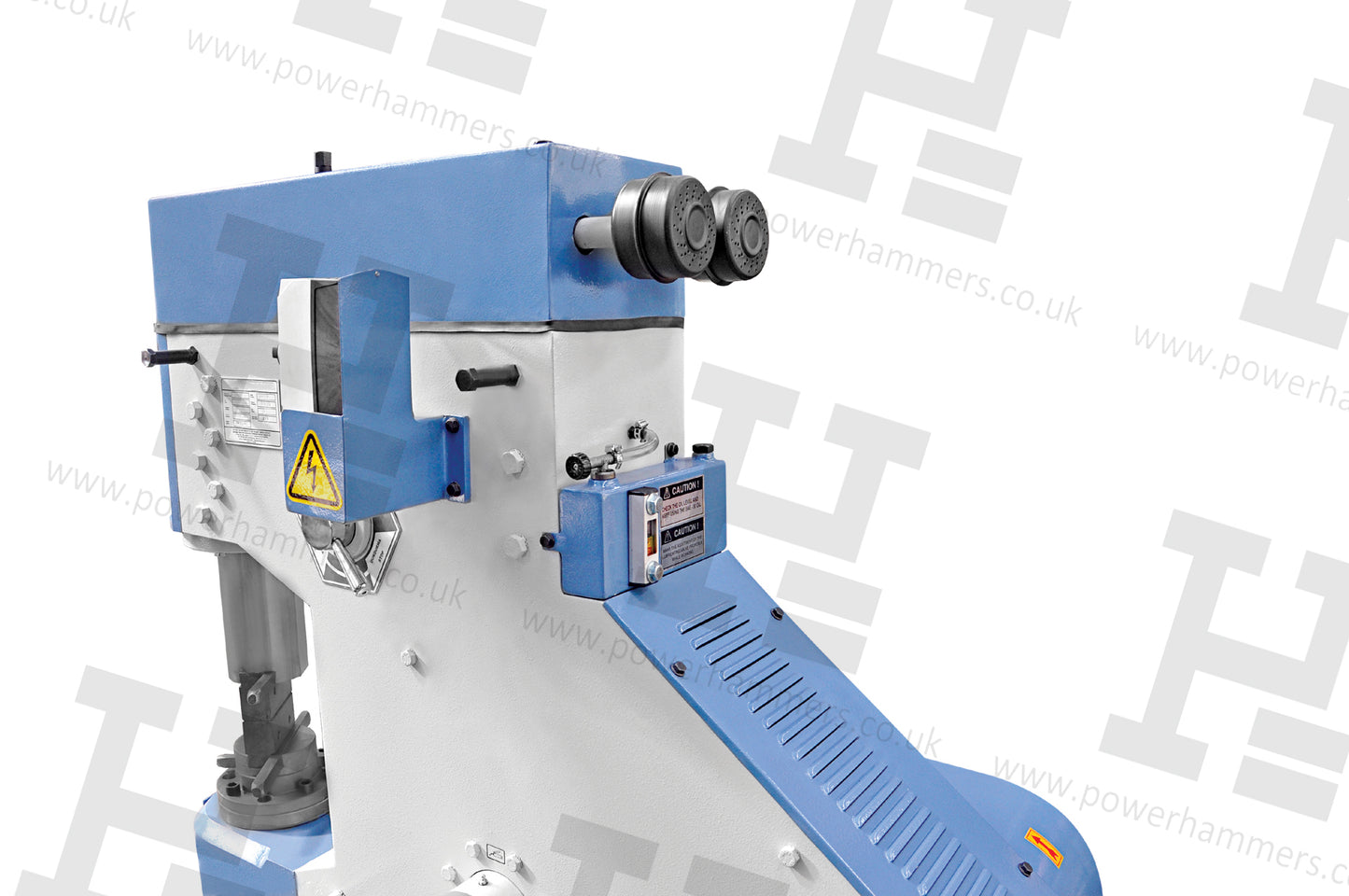

- Precision Engineering: Designed for accurate and repeatable strikes, ideal for detailed and dynamic forging work.

- Compact Efficiency: A small footprint with integrated forklift points ensures straightforward installation and relocation.

Specifications

| Specification | Details |

|---|---|

| Ram Weight | 60 kg |

| Motor Power | 7.5 HP (approximately 5.6 kW) |

| Machine Weight | Approximately 1,878 kg (4,140 lbs) |

| Dimensions (W × L × H) | 787 mm × 1,905 mm × 1,930 mm (31" × 75" × 76") |

| Footprint | 559 mm × 1,905 mm (22" × 75") |

Why Add the SPH-60 to Your Workshop?

The Say-Mak SPH-60 combines heavy-duty forging power with precision control, making it the ideal tool for increasing productivity and tackling complex projects. Its robust construction and compact design ensure it fits seamlessly into any workspace, from small artisan workshops to larger industrial settings.

Take your forging capabilities to the next level with the SPH-60 – a reliable and efficient powerhouse that delivers every time.